Research and

development lab

Uno dei più

grandi laboratori

d’Europa

In house

performance

review

Technical equipment

The lab is equipped with climatic rooms, high profile systems and equipment for the analysis and energy certification of the manufactured machines.

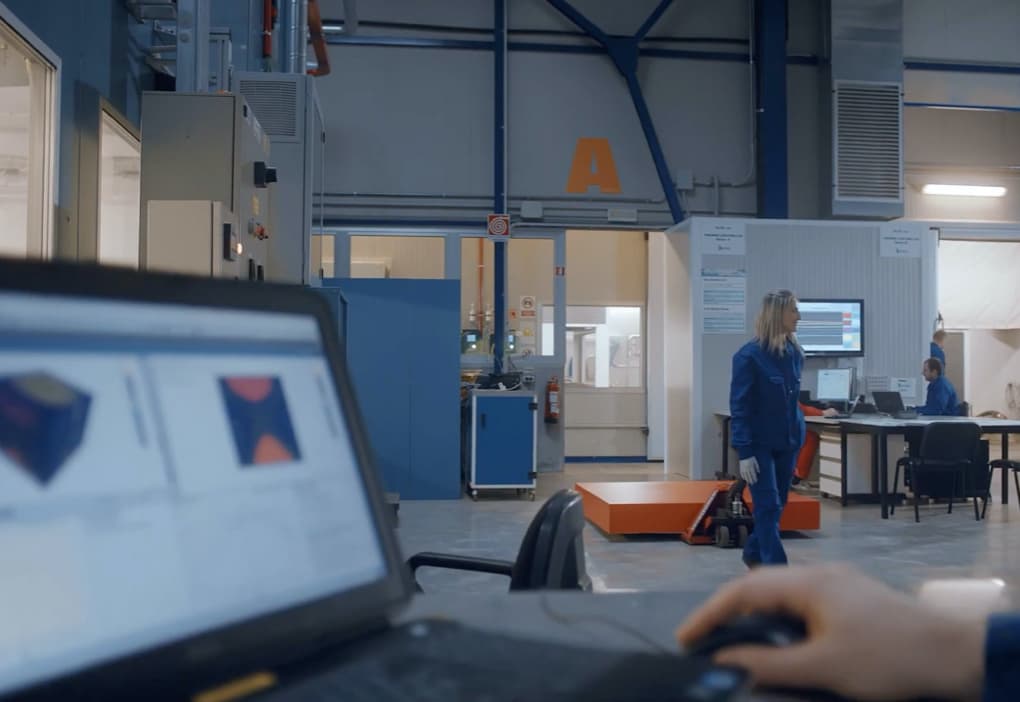

A-B Testing Rooms

Equipped with a double hydraulic system and removable dividing wall to allow the simultaneous testing of 2 chiller units or heat pump units, with air or water condensation, with heat recovery and split units.

C Testing Room

To be used for terminal units testing and small chillers-heat pumps up to 12 kW of power.

D Testing Room

To be used for terminal units testing and small chillers-heat pumps up to 60 kW of power.

Three areas for noise level testing

Two internal for components and small machines, and a larger external one for measurements on large units.

Research and Development lab

If you want to know more about the technical equipment, performed measurements and efficiency certifications produced in our lab, download the in-depth brochure.

Prototype Department

Dedicated to the manufacturing of prototypes, it is equipped with the tools required to apply quick modifications during the testing phase.

Find a reseller in your area for a customized offer on Rhoss air conditioning solutions.